You may love the warmer temperatures in the spring and summer — but your industrial air compressor does not. Your compressed air system requires extra maintenance in the hot summer months to prevent unexpected shutdowns and damage to system components. Here’s how increased temperatures in the summer months impact your compressed air system — and what you can do to prevent costly damage.

Summer Heat and Your Air Compressor — Key Risks & Solutions

| Risk | What Happens | What You Can Do |

|---|---|---|

| Overheating | High ambient temperatures make it harder to keep compressors cool, leading to shutdowns or damage. |

|

| Increased Moisture | Warm air holds more humidity, causing more condensate in the system. |

|

| Lubricant Breakdown | Heat causes oil to break down faster, reducing lubrication and increasing wear. |

|

| Reduced Efficiency | Compressors work harder in hot, humid conditions, using more energy. |

|

Risk 1: Overheating

Your air compressor already puts out a lot of heat on its own: a 100 HP industrial air compressor produces enough thermal energy to heat four homes through the winter! This is a natural consequence of air compression; as a gas is compressed, heat (called the “heat of compression”) is produced. In cooler weather, the excess heat is easily dissipated and may even be welcome. But in the summer months, hot ambient temperatures make it harder to shed excess heat and put extra stress on your air compressor.

Most industrial air compressors have an automatic safety shutoff that will shut down the compressor if it begins to overheat. If your air compressor is shutting down during the summer months, you need to find ways to help it shed that excess heat.

If you don’t have a shutoff system, or if it isn’t working correctly, overheating the compressor is bad news. The discharge temperatures for your air compressor should not exceed 225°F. When temperatures rise above this limit, heat can cause a compressor failure as lubrication breaks down or vaporizes, electrical components start to melt, and insulation is destroyed. Even many short time periods running above standard operating temperatures can shorten the life of your compressor motor by 30-50%. Oil temperatures at 200 degrees will cut the oil life in half. If allowed to continue running in an overheated state, the compressor will eventually break down entirely and may be costly or unrepairable.

What You Can Do: Preventing Air Compressor Overheating

There are several steps you can take to take the pressure off of your air compressor and cooling systems.

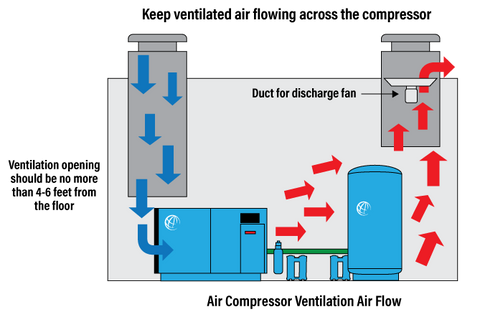

- Improve ventilation: If your air compressor is located outside, ventilation is not likely to be a problem. But for industrial air compressors operating indoors, ventilation is critical in the summer months. Crossflow ventilation carries away excess heat and helps your compressor cooling systems work more efficiently. Make sure that air can flow freely through the compressor room and around the compressor. Remove any obstructions to the ventilation system. Keep the compressor room as cool as possible to reduce strain on the air compressor cooling system. If possible, vent hot air generated by the compressor coolers to the outside.

- Check air compressor coolers: Keeping the air compressor cooling systems in good working order is essential when ambient temperatures rise. Clean the air compressor coils and the heat exchanger. For water-cooled heat exchangers, check the water supply for scale and dirt buildup and ensure that adequate water is available for proper cooling. Make sure the cooling water supply is maintained at an appropriate temperature. For air-cooled heat exchangers, clean any dirt buildup, make sure there are no clogs in the system and check fans to ensure they are working properly.

- Clean the compressor motor cabinet: Dust and dirt act as a layer of insulation on the compressor components, causing it to run hot. Blow excess dirt out of the compressor cabinet, clean the fan and make sure it works, and clean or replace filters for the electrical cabinet. Be sure to use appropriate precautions when cleaning the electrical cabinet; turn off the power supply for the compressor and use lock-out/tag-out procedures for safety.

- Keep filters clean: Blocked filters will cause your air compressor motor to work harder, generating more heat. Keep air flowing smoothly through your compressed air system by checking air compressor filters frequently and changing them as they become loaded. Be sure to include inline air filters, intake filters, and cabinet filters.

Steps to Prevent Compressor Overheating

| What to Do | Why It Matters | |

|---|---|---|

| 1. Improve Ventilation | Make sure your compressor room has adequate airflow. | Trapped hot air raises ambient temps and strains cooling systems. |

| 2. Clean Cooling Components | Regularly clean radiator fins, intercoolers, and oil coolers. | Dust and debris reduce heat transfer and cause temperature spikes. |

| 3. Check Oil Levels and Quality | Inspect and change oil more frequently in the summer. | Heat breaks down lubricants faster, reducing cooling and protection. |

| 4. Monitor Ambient Temperatures | Install a thermometer or sensor to track room temps. | Awareness helps you react before overheating becomes a problem. |

| 5. Add Supplemental Cooling (If Needed) | Use fans, ducting, or even spot cooling for hot zones. | Helps offset extreme temps when HVAC isn’t enough. |

Risk 2: Excess Moisture

Warm air holds more moisture than cold air. Unless you are living in a desert clime, summer brings high humidity along with higher temperatures. This added moisture in the air means more water ends up in your compressed air system. (To understand why, read this: Relative Humidity vs. Dew Point in Compressed Air Systems.)

Excess moisture causes all kinds of problems for your compressed air system, pneumatic tools and production processes.

- Moisture buildup inside the compressor, air receiver tanks, and other components will lead to corrosion over time. Corrosion weakens your system, allowing leaks to develop or resulting in a buildup of debris that can block air lines.

- Excess moisture in the compressed air supply can damage pneumatic tools, valves, cylinders and other pneumatic equipment.

- Many production processes are highly moisture sensitive, especially paint lines, food processing and pharmaceutical applications, chemical production and medical applications. Excess moisture may result in corrosion, damage, or spoilage of raw materials or finished products.

What You Can Do: Eliminating Excess Moisture in Compressed Air Systems

To maintain clean, dry air throughout the summer months, step up all of your moisture-fighting protocols for your compressed air system. Specifically:

- Check drains more frequently: More water vapor going into the compressor means more liquid water coming out. If you have manual drains on your air compressor, air dryers and receiver tanks, they will need to be emptied more often — perhaps several times a day. Make sure that automated drains are working properly and replace them if they are not. Also, check and clean drain filter traps and make sure the oil/water separator is working. If you don’t already have an automated drain valve, this is a great time to have one put in. Electric drain valves are set to open on a schedule. You may need to adjust the timing for these drain valves for the summer months. A zero-loss condensate drain valve opens automatically when enough moisture has accumulated. These drain valves self-adjust for higher humidity since they open exactly as often as needed to drain moisture as it accumulates. In addition to simplifying maintenance, they save energy and reduce compressed air loss since they do not open unless the liquid is present.

- Give your air dryers a checkup: Your air dryers will be working harder in the summer months, so make sure they are up to the task. Before things get too hot and sticky, check your air drying system to make sure it is operating efficiently. For refrigerated air dryers, clean condenser coils, check the refrigerant level and ensure that refrigerant is circulating properly and is not contaminated. For desiccant air dryers, change filters, check controls and make sure that desiccant materials have not been contaminated with oil. Change the desiccant material if it is contaminated, discolored, or at the end of its life (~5 years for heatless activated alumina systems and 2-3 years for heated regenerative dryers). If you’re not sure, have the desiccant tested to make sure it is still doing its job.

Eliminating Excess Moisture in Compressed Air

| What to Do | Why It Matters | |

|---|---|---|

| 1. Check Dryer Operation | Ensure dyers are operating properly. | Dryers are an essential element of moisture management. |

| 2. Drain Condensate Frequently | Check and empty condensate traps and drains often. | Higher humidity = more condensate, requiring more frequent draining. |

| 3. Use an Aftercooler | Add an aftercooler between the compressor and dryer. | Aftercoolers remove 60-70% of moisture to reduce strain on dryers. |

| 4. Monitor Dew Point | Use dew point monitors to track system moisture levels. | Stay ahead of problems with real-time data. |

| 5. Right Size Your Dryer | Upgrade your refrigerated or desiccant air dryer if it’s not keeping up. | An undersized dryer may not keep up with moisture levels in the summer. |

Risk 3: Lubricant Breakdown

Oils and lubricants also break down more quickly in hot temperatures, which can lead to excess wear and tear on the air end.

- Lubricants thin as temperatures rise. When this happens, the oil doesn’t adhere to surfaces as well and some parts of the air end may not get the lubrication they need. As a result, these parts experience more friction and wear and tear, reducing the life of the air end.

- Oils degrade rapidly at very high temperatures — especially mineral or petroleum-based lubricants. Petroleum-based lubricants start to oxidize in temperatures above 240°F. As the oil oxidizes, varnish and deposits form on oil-lubricated surfaces. This decreases the ability of the oil to protect lubricated parts. Synthetic lubricants offer better temperature protection, but can still break down or vaporize when temperatures are excessive. Compressor oil running at 200 degrees will cut the oil life in half.

What You Can Do: Monitoring Air Compressor Oil Levels

Your oil will require some extra attention in warmer weather.

- Check the fluid circulation system: Make sure that oil is circulating appropriately through the system, if varnishing is observed use a fluid designed for Screw compressors that removes the varnish in the air end and coolers.

- Increase your oil checks: Air compressor oil levels should be checked more frequently in the summer months. For oil-lubricated air compressors, check oil levels 3–4 times per week.

- Inspect oil regularly for dirt and contamination. Change the oil if it appears dirty or on the schedule recommended by your owner’s manual. Typically, this will be every 4,000–6,000 service hours for a rotary screw air compressor or every 3 months for a reciprocating air compressor. In the summer, you may find that you need to accelerate this maintenance schedule.

Maintaining Oil Levels

| What to Do | Why It Matters | |

|---|---|---|

| 1. Check Oil Levels Frequently | Inspect oil levels daily or weekly, depending on usage. | Low oil levels reduce lubrication and cooling, increasing wear and risk of overheating. |

| 2. Look for Oil Discoloration or Contamination | Check for changes in oil color, thickness, or signs of contamination or varnish. | Contaminated oil can’t properly protect internal components and may indicate other system issues. |

| 3. Use the Right Oil Type | Follow the manufacturer’s recommendation for oil type and viscosity, especially in high-heat conditions. | Using the wrong oil can lead to breakdown under summer heat and reduce compressor life. |

| 4. Follow a Regular Oil Change Schedule | Replace oil based on hours of operation — and more frequently during hot months. | Heat accelerates oil degradation, so timely changes are critical to performance and protection. |

| 5. Check for Leaks Around Seals and Hoses | Inspect common leak points and repair promptly. | Even small leaks lead to low oil levels and potential system damage over time. |

Risk 4: Cracked Belts, Seals and Couplings

Extreme temperatures and temperature fluctuations can be hard on air compressor components — especially rubber or polymer-based belts, seals and couplings. These components are more likely to fail when stressed by high temperatures or repeated temperature fluctuations.

What You Can Do: Inspecting Belts, Seals and Couplings

Make sure you stay on top of your maintenance inspections during the summer months.

- Regularly inspect all components: Check rubber and polymer-based components frequently for cracks and tears. Replace worn belts, seals, gaskets and couplings immediately to prevent leaks in your compressed air system or problems with your compressor.

- Run a leak test: Another way to determine whether or not you have a problem with couplings, hoses and seals is to run a leak test. These tests can locate leaks that are too small to be detected by human senses or in areas that are difficult to inspect. Fixing compressed air leaks in the plant will reduce the load on the compressor and save energy. Read more: How to Locate Compressed Air Leaks.

Inspecting Your System Components

| What to Do | Why It Matters | |

|---|---|---|

| 1. Check Rubber Components for Cracks or Wear | Inspect belts, seals, gaskets, and couplings regularly for cracks, brittleness, or signs of deterioration. | Heat and temperature swings accelerate aging in rubber and polymer parts, increasing the risk of failure. |

| 2. Replace Worn Parts Immediately | Don’t wait for failure — replace damaged belts, seals and couplings as soon as wear is detected. | Prevents air leaks, system inefficiencies, and unplanned downtime. |

| 3. Tighten Hardware and Mounting Points | Ensure all fasteners around belts, seals and couplings are secure. | Heat and vibration can loosen connections over time, leading to leaks or failure. |

| 4. Run a Leak Test | Use ultrasonic testing to identify hidden leaks in the system. | Small leaks waste energy and force your compressor to work harder — especially costly in summer. |

Get Your Air Compressor Ready for Summer Heat

Don’t wait for high temperatures to cause problems. Summer heat can take a serious toll on your air compressor — but with the right prep, you can avoid costly downtime, protect your equipment, and keep your operations running smoothly. Get ahead of the heat by scheduling a maintenance check before temperatures rise.

Need help? The experts at Fluid-Aire Dynamics are here for you. We specialize in industrial air compressors and offer comprehensive service and support — from system inspections to maintenance, repairs, and upgrades. We can evaluate your system, perform all recommended preventive maintenance, and get your compressed air system ready to beat the heat.

Contact us to schedule a service call.