Do you know how to calculate dew point vs. relative humidity for your compressed air system? Understanding these measures and the relationship between dewpoint and relative humidity will help you maintain your compressed air system at optimal performance. To minimize condensation problems in your system, it is important to know how much moisture is in the air vs. how much moisture the air is capable of holding. Measuring or calculating your dew point and relative humidity (RH) can help you avoid problems with your compressed air system and production applications. Here’s how to know if your pressure dew point is too high — and what you can do to fix it.

Relationship Between Relative Humidity and Dew Point

What is relative humidity vs. dew point? Dew point and relative humidity are related concepts; dew point can be expressed as the temperature and pressure at which air is at 100% relative humidity:

- The dew point is the temperature at which water turns from a vapor into a liquid at a given pressure. The dryer the air, the lower the dew point.

- The relative humidity is a measure of how much water vapor is in the air relative to the maximum amount it can hold. Relative humidity depends on both temperature and pressure. Air can hold more water vapor at warmer temperatures than at cooler temperatures and lower pressures vs. higher pressures.

When air reaches saturation, or 100% relative humidity, it cannot absorb any more water, and additional water falls out as condensation.

What Is Dew Point?

The dew point is the temperature at which water vapor in the air starts to condense into a liquid. The dew point is a measure of how much moisture is in the air. A higher dew point means there is more moisture in the air.

The amount of water that can be held in a volume of air is directly related to its temperature. Warmer air can hold more water vapor than cooler air. As air is cooled at constant pressure, it becomes more and more saturated. As the temperature continues to drop, excess water condenses as a liquid. The temperature at which this happens is the dew point.

We see this in action in nature at atmospheric pressure. Warm daytime air holds more moisture (or humidity). As temperatures cool overnight, dew forms on grass and other surfaces. The more humidity in the air, the higher the temperature at which condensation starts to form. In very low humidity, condensation may not form until temperatures are below the freezing point of water. We call this the frost point.

Differences Between Atmospheric Dew Point, Pressure Dew Point, and Frost Point

Atmospheric dew point, pressure dew point, and frost point are related terms, but they have slightly different definitions and applications:

- The atmospheric dew point is the temperature at which liquid water falls out of the air at normal atmospheric pressures (~14.7 PSI at sea level, or ~1 bar). The atmospheric dew point is related to the relative humidity in atmospheric air; the higher the humidity (the more moisture is in the air), the higher the temperature at which dew will begin to form. Atmospheric dew point is an important concept in meteorology.

- Pressure dew point is the dew point of air under pressure, such as in a compressed air system. The compressed air pressure dew point is a measure of how much moisture is in the air at a given pressure. The higher the pressure, the less moisture the air is able to hold, resulting in a higher dew point temperature. Different applications have different requirements for pressure dew point.

- The frost point is the temperature at which water vapor condenses into frost. It is usually a temperature below 0°C (32°F). You have a frost point instead of a dew point when air is very dry, resulting in a dew point below the freezing temperature of water.

What Is Relative Humidity?

Relative humidity (RH) is a measure of how saturated the air is — in other words, how much moisture is in the air relative to the total capacity of the air to hold moisture. Remember, this is a relative measure. RH alone does not tell you how much total moisture is in the air. It simply tells you how close you are to saturation for a given temperature and pressure. At 100% RH, the air is completely saturated. Any additional moisture entering the air at this point will cause condensation to start to form. At 50% RH, the air can continue to absorb additional moisture without causing condensation.

Like dew point, relative humidity is directly related to temperature. A 40°F day with 100% humidity has much less moisture in the air in absolute terms than an 85°F day at 50% humidity. That’s why cooler days feel drier, even if the reported RH is the same. As air cools, RH rises, even though no additional moisture has entered the air. When we reach the temperature where RH is 100%, we have hit the dew point.

Dew Point vs. Relative Humidity Chart

This chart shows the relationship between relative humidity vs. dew point temperature. At 100% humidity, dew point temperature and air temperature are the same (the far right diagonal line). If the humidity is 50% (blue diagonal line) on a 90°F day (blue horizontal line), the dew point temperature is 70°F (blue vertical line). Liquid water will start to condense when temperatures fall to this level. At 5% humidity on an 85°F day, the dew point temperature is 10°F; because this is less than the freezing point of water (32°F), frost will form instead of liquid dew (making this a frost point).

Calculating Pressure Dew Point and Relative Humidity for Compressed Air

The amount of moisture in the air of your compressed air system depends in large part on the humidity of the air outside. The more moisture present in the intake air, the more water vapor (and potentially condensation) will end up in your compressed air system.

The dew point in a compressed air system is known as the pressure dew point (PDP), e.g., the dew point at the PSI at which the system is operating. (This is contrasted to the atmospheric dew point or the dew point of air at atmospheric pressure.) RH and dew point are specific to the pressure the air is under. As air is pressurized, excess moisture is squeezed from the air like water from a sponge.

To visualize this, remember that the water-holding capacity of air depends on its temperature. That means that 1 m3 of intake air and 1 m3 of compressed air at the same temperature can hold the same amount of water. But, during compression, we’re squeezing a lot more air (in terms of actual air and water vapor molecules) into our 1 m3. If we raise the pressure from 1 bar (atmospheric pressure) to 8 bar (roughly 116 PSI), we are squeezing that 1 m3 of intake air into 1/8 m3 of space, so our 1 m3 of compressed air now contains eight times the water vapor as 1 m3 under atmospheric pressure. If the air was already saturated going in (100% RH), all of that excess water will fall out as condensation.

It is important for manufacturers to know the dew point and relative humidity for the pressures and operating temperatures at which their system is running. In other words, how much moisture is in the air in the system (absolute humidity) and how close they are to the dew point of their system (100% relative humidity or saturation point).

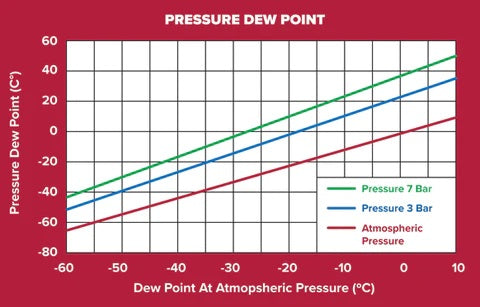

Pressure Dew Point Chart (Dew Point of Compressed Air)

This chart shows the relationship between the dew point of air at atmospheric pressure vs. the dew point of air at 7 bar (~102 PSI) and 3 bar (~44 PSI). At higher working pressures, the pressure dew point (the temperature at which liquid falls out of the air) is also higher.

Compressed Air Temperature and Pressure Dew Point

Remember that the saturation vapor pressure for air inside your compressed air system is dependent on the temperature — and the temperature of that air is changing as it goes through the system. Air coming directly out of the compressor will be very hot, so it is able to hold more moisture than cooler air. That’s why condensation tends to fall out of compressed air as it sits in your air receiver or moves through the air lines. Just like dew forms overnight as air cools, condensation will start to form when air in your compressed air system cools to the dew point.

How to Measure Pressure Dew Point for Compressed Air Systems

Dew point measurement is usually pretty simple. The easiest way to determine the pressure dew point (PDP) for your compressed air system is to measure it directly. You can measure the PDP for your compressed air system using a dew point sensor. The sensor measures temperature and traces moisture to determine the point at which condensation starts to occur.

If your production processes are highly sensitive, you can use a stand-alone hygrometer to precisely measure moisture levels in process air. A hygrometer measures moisture in the air directly using evaporative cooling (comparing wet bulb and dry bulb temperatures) or via a material that contracts and expands with changes in humidity. Modern digital hygrometers use resistance or capacitive sensors to measure moisture levels and determine the dew point.

If you are using air dryers, they will have a built-in dew point sensor to monitor the dew point of air and control the dryers to maintain moisture levels within your specifications. It is a good idea to double-check and calibrate the system with an external hygrometer at least once a year or if you are experiencing problems that make you suspect your dryer is not maintaining the correct dew point.

Aire Tip: Most air dryers have integrated dew point sensors to continually monitor the dew point of your system.

How to Calculate Dew Point and Relative Humidity for Compressed Air

It is also possible to calculate the dewpoint and relative humidity for your compressed air system. To do this, you have to know how much moisture is in the air coming into the compressor. We will first need to calculate the absolute humidity of intake air — that is, the total amount of water vapor present in a given volume of air. We can figure out absolute humidity in grams per cubic meter if we know the relative humidity and temperature of the intake air. To calculate absolute humidity in g/m3, you will need the intake air temperature in Celsius and the RH (expressed as a %). You will also use the natural log (e). The formula is:

Or, you can use one of many handy online RH to AH calculators to do this for you.

Now, we need to determine the moisture-carrying capacity (also known as the saturation vapor density or saturation point) of the compressed air. Again, this depends on its temperature. This is easiest to do using a saturation curve or table, like this one:

The dew point of your system is the point at which the RH of your compressed air is 100%, or when the absolute humidity of air coming in equals the moisture-carrying capacity of the compressed air. RH is calculated as:

RH = (actual vapor density/saturation vapor density) *100

If RH is greater than 100, you will have condensation. A number lower than 100 gives you the RH of your system and tells you how close you are to the dew point.

Let’s look at an example:

- Intake air temperature is 20°C (68°F) with RH of 60%, for absolute humidity (actual vapor density) of 10.3 g/m3 (from NOAA calculator).

- The temperature of compressed air is 40°C (104°F). Saturation vapor density = 51 g/m3 (from the chart).

- Air is compressed from 1 bar to 8 bar. The new absolute humidity of the air is 10.3 g/m3 x 8 = 82.4 g/m3.

- RH = (82.4/51) * 100 = 162%

Since 100% is the maximum RH, we know that we will have condensation in this example.

Now, let’s lower the incoming RH to 20%:

- Actual vapor density = 3.4 g/m3 (from NOAA calculator)

- With the same compression, new absolute humidity = 3.4 g/m3 x 8 = 27.2 g/m3

- RH = (27.2/51) * 100 = 53%

In this case, RH is lower than the saturation vapor density inside the system, so condensation will not occur.

Why Does Dew Point Matter for Compressed Air Systems?

Dew point is an important aspect of compressed air quality. It tells you how much moisture is in your air. If the dew point is too high – that is, there is too much moisture in the compressed air supply – it can cause problems for the compressed air system, the tools, and equipment using the air, or product or process quality. If your air must meet ISO standards for purity, a dew point that is too high may also put you out of compliance. To protect your system, prevent problems with air-using tools, and ensure product quality, make sure your pressure dew point is within the appropriate specs for your application.

Common Problems Caused By Moisture in Compressed Air Supply

Excessive moisture in compressed air systems can cause a number of problems for your system and for tools and final products. Some of these include:

- Corrosion: Moisture leads to corrosion of metallic parts, which can include compressor components, distribution piping systems, and tools and equipment that use compressed air.

- Product quality: Many applications (such as paint booths, pharmaceutical production, food processing, chemical manufacturing, and others) are sensitive to moisture in process air. For example, excess moisture may cause caking of dry powders, food spoilage, bubbling and poor adherence of paints and coatings, or delamination of plastics made with injection molding. If moisture leads to corrosion, particles can flake off and foul production processes.

- Freezing: Excess condensation that forms in control lines, valves, and hoses is at risk of freezing when temperatures drop. Because water expands when it freezes, this can lead to equipment damage.

- Control problems: Water and rust in control lines may lead to blockages or false readings on air compressor instruments

- Microbial growth: Liquid water in control lines and air lines becomes a breeding ground for molds and bacteria, which can create problems for products (especially food or pharmaceuticals) or create a health hazard for employees.

- Poor lubrication: Water and rust inside the compressor or air tools will degrade lubrication efficacy and lead to damage to moving parts.

- Compliance problems: If your air must meet ISO 8573 standards for compressed air purity, excess moisture in the air will put you out of compliance.

What Should the Dew Point Be for a Compressed Air System?

A continuous dew point monitor will tell you the dew point at which your system is currently running. Typical dew points for compressed air systems are between 50°F and 94°F. For many applications, you will want to lower the dew point of your system by removing moisture from the air. A combination of air dryers, wet storage, and filters are used to remove excess moisture from the air and lower the dew point to the standard required for the application.

- For standard manufacturing environments (e.g., using air tools, running pneumatic conveyors, etc.), a pressure dew point of ~50°F or even higher is adequate to keep liquid water from forming in the distribution system, tools, and equipment.

- Some applications — such as paint booths, printing, food processing, and pharmaceuticals — require super-dry air. These applications may require pressure dew points down to -40°F or even -100°F.

Aire Tip: For most applications, maintaining an RH of 75% or lower relative to the dew point of your system will be adequate to keep compressed air lines liquid-free.

Dew Point and ISO Requirements for Compressed Air

If your application requires air to meet ISO classes for purity, it is important to meet the dew point requirement for allowable water content in the application. Water content is one aspect of air purity defined by ISO 8573 (the others are particulate content and oil carryover). Under this standard, air in purity classes 6 and below must meet strict vapor pressure dew point requirements. (For classes 7-9, moisture content is measured in g water/m3 air.)

- Class 6: ≤ 50°F vapor pressure dew point

- Class 5: ≤ 45°F vapor pressure dew point

- Class 4: ≤ 37°F vapor pressure dew point

- Class 3: ≤ -4°F vapor pressure dew point

- Class 2: ≤ -40°F vapor pressure dew point

- Class 1: ≤ -94°F vapor pressure dew point

- Class 0: process specific

How to Lower Dew Point in Compressed Air Systems

You can lower the dew point of your compressed air system by removing excess moisture from the air. Compressed air dryers are needed for most industrial applications to reduce the dew point to an acceptable level for air-using processes. After-coolers, air receiver tanks, and water separator filters can also help to remove excess water from the system and support the air dryers.

Read more: Getting Rid of Moisture in Your Compressed Air System.

Air Dryers

Air dryers are the most effective method of removing excess moisture and lowering the dew point of compressed air. If you need to have air with a pressure dew point below 50°

F, you will need some type of air dryer. There are two types of dryers:

- A refrigerated air dryer works by chilling air to 33-40°F, allowing excess water to condense, and then bringing air back up to ambient temperatures before adding it to the system. This lowers the dew point to 33-40°F (the temperature to which the air was chilled). Refrigerated dryers lower the dew point adequately for most applications.

- Desiccant air dryers remove water from the air through a chemical process. They can reduce the dew point to -40 to -100°F, creating ultra-dry air for sensitive applications.

After-Coolers and Air Storage

Adding after-coolers and a wet storage tank to your system can also help you reduce the dew point of your air while reducing the pressure on the air dryers. Air cools down naturally in the after-cooling system or an air receiver tank installed in between the coolers and the air dryer. This allows the majority of moisture to fall out of the air before it hits the dryers.

Filtration

A water separator filter or water trap removes excess moisture that falls out of compressed air as a liquid via mechanical separation.

Aire Tip: Drain excess water daily from air receiver tanks and other places water is likely to condense. Programmable or zero-loss drain valves will do this for you automatically.

Need Help Lowering the Dew Point of Your Compressed Air?

Fluid-Aire Dynamics has air-drying solutions to improve your processes. We can help you determine the required dew point for your applications and design a drying system to ensure a consistent supply of clean, dry air.

Contact us for an evaluation.

©2026 Fluid-Aire Dynamics, Inc. All Rights Reserved.