Today, many industries are setting green initiatives to become more environmentally friendly. Green processes make it much easier to manage this switch while supporting business needs. Using eco-friendly air compressors is one notable way industries can benefit the environment, human health, and company efficiency and spending.

Air compressors use less energy than other tools, and businesses can bring this solution to the production line for a noticeable difference. In this guide, you'll discover why you should go green, how to switch and the benefits of oil-free air compressors.

Reasons to Consider Environmentally Friendly Air Compressors

Sustainable business practices offer positive environmental impacts while helping companies see additional benefits like lower costs and less energy consumption. Minor upgrades like more efficient equipment can significantly impact many businesses.

Some benefits of environmentally friendly air compressors include:

- Lowering energy/fuel consumption: Switching to eco-friendly air compressors can reduce your business's carbon footprint. These compressors decrease energy usage and emissions, minimizing your environmental impact and helping you save money over time through lower energy bills.

- Cutting business costs: On top of saving energy, many air compressors require less preventative maintenance over time, reducing repair costs and downtime while boosting productivity and efficiency. These little savings make a significant impact over the years and allow you to create even more cost-effective initiatives.

- Improving air quality: Oil-free air compressors don't emit waste gases or polluting smoke that could compromise work health or harm the environment. These compressors operate without oil, allowing your business to create cleaner facility air.

- Reducing oil contamination: Traditional air compressors always present the risk of oil contamination. When you experience contamination, you face a valuable loss in production and time. You have to increase spending to service the production line and the machine, and oil contamination can stop production until you fix the problem. With oil-free air compressors, you can rest assured production will move efficiently, and you can save money on avoiding repairs and fixing contamination issues.

- Supporting a positive reputation: Consumers are growing increasingly aware of environmental impacts. Many people want to reduce their carbon footprint and choose to interact with brands that share their values. Switching to an environmentally friendly oil-free air compressor can boost your image and reputation. Advertising your green initiatives will show your customer base you value their needs and wants and care about the environment. This effort can help you become an industry leader and more welcoming of potential customers or clients.

- Reducing noise levels: Gas-powered air compressors often have a noisy operation. Their engines make it challenging to reduce noise, which can impact productivity. Many eco-friendly compressors use electricity, allowing you to operate them at quieter levels to support your workers. Additionally, many new models feature aluminum or steel walls and rubber components that can further dampen sound.

5 Ways to Make Your Air Compressors More Eco-Friendly

Below, find ways to create green air compressor processes, so your business can reduce its carbon footprint and work toward a more sustainable future.

1. Have a Maintenance Plan

Like many pieces of equipment, regular maintenance ensures efficiency and productivity. Regular maintenance will keep your compressor in the best condition to maximize business function and help your company save money on future repair or replacement costs.

If your air compressor is functioning poorly, it can consume high amounts of resources, decreasing your productivity and impacting sales. Your air compress will naturally experience wear and tear that can affect its efficiency over the years, but proper maintenance and routine evaluations can help you catch minor problems before they become detrimental.

Create a maintenance schedule for your air compressors to keep them in the best working order. Plan to service your compressors twice a year and request a yearly professional audit. Immediately report any issues you note during your regular maintenance checks.

2. Use High-Quality Fluids and Lubricants

Air compressors require lubricants and fluids for optimal function. However, leaks can contaminate products, waterways and groundwater. You can become more eco-friendly by investing in green products that will have less impact on the environment and ensure your compressor remains in optimal condition to minimize performance issues.

3. Integrate Pest Control

Insects, snakes, rodents and other pests can ruin machinery in any industry. Although many businesses opt for harsh chemicals to keep pests away, these products can create a less safe working environment for employees.

Pest management is a powerful tool that spans beyond chemicals and artificial products while keeping your employees and business efficient. Monitoring holes in the system, watching for leaks from your compressor and covering ductwork and vents are excellent ways to minimize your chemical use that threatens employees and the environment.

4. Minimize Energy Consumption

Reducing energy consumption is an excellent way to minimize your environmental impact. Eco-friendly technology can help reduce your carbon footprint while keeping your compressors efficient.

For example, variable speed drive technology can enable your compressor to adjust its speed as air demands change, allowing you to save on energy, reduce wear and tear, minimize energy consumption and extend the equipment's life span. You can also find technology to monitor the air compressor's performance and remotely control the settings to ensure all energy use is valuable.

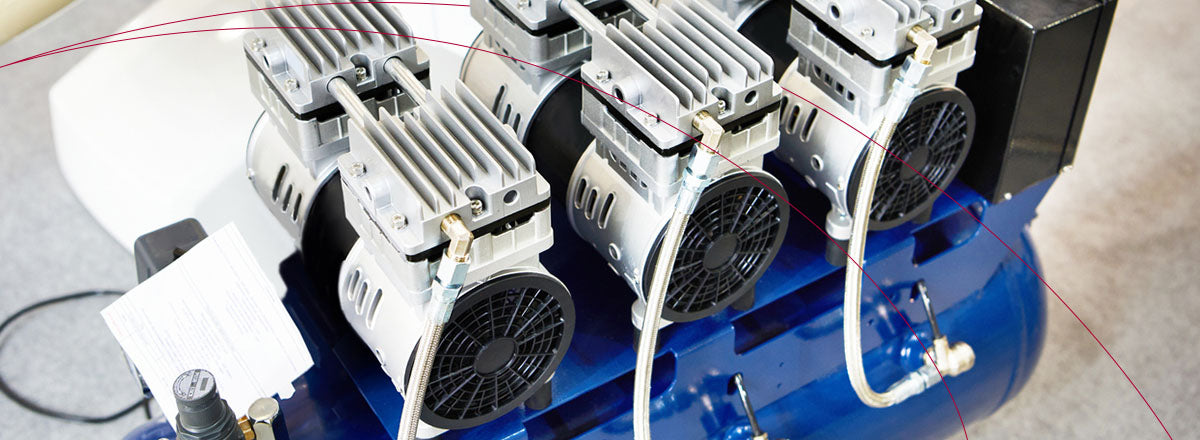

5. Switch to Oil-Free Air Compressors

Although upgraded components and processes can help your business go green, sometimes, the best step is to replace the system. If your current compressors need intense maintenance or are reaching the end of their lives, switching to oil-free air compressors is a comprehensive solution for your business and the environment.

The Environmental Benefits of an Oil-Free Air Compressor

Oil-free air compressors offer businesses an easy way to go green and show their commitment to the planet. These newer models have a range of benefits for your business and the environment. Oil-free compressors consume less energy than their counterparts and require less demand from your facility resources. This allows you to cut costs and save money over time while having a productive line and delivering high-quality products or services.

Additionally, oil-free compressors have zero emissions and meet environmental compliance. This equipment can improve facility air and help employees remain happy and healthy. Furthermore, you can eliminate the possibility of oil contamination, as these units don't require oils to complete business functions, allowing you to save more money through efficient practices.

Go Green With an Eco-Friendly Oil-Free Air Compressor

At Fluid-Aire Dynamics, we understand the importance of finding the best practices to support your business and the environment. We've been solving gas and compressed air problems for nearly three decades, giving us in-depth knowledge and expertise in the industry.

Fluid-Aire Dynamics is committed to doing the right thing and ensuring you can provide the best service for your customers. We know that real solutions have quality system designs, solid information and precise implementation behind them. We feel confident that we can help you create the solution your business needs with our selection of oil-free air compressors.

Contact Fluid-Aire Dynamics for more information about oil-free air compressors to discover what they can do for your business and the environment.

©2026 Fluid-Aire Dynamics, Inc. All Rights Reserved.