Fluid-Aire Dynamics: The Leading Compressed Air Solutions Company

Specializing in compressed air services in Chicago, Milwaukee, Minneapolis, Detroit, Philadelphia. System design, equipment, installation, parts, supplies, maintenance, and repair of industrial and commercial rotary screw air compressors. Call or click now for Fluid-Aire Dynamics’ outstanding customer support.

Inbound Calls Answered

by a Human

Average Emergency

Response Time

Total Active

Customers

Customer Satisfaction

Score (NPS)

Our Compressed Air Services

Fluid-Aire Dynamics is the leading specialist in compressed air systems across Chicago, Milwaukee, Minneapolis, Detroit, Philadelphia. We know rotary screw compressors from top to bottom: installation, maintenance, and repairs! Our factory-trained technicians will ensure the reliability, performance and energy efficiency of your compressed air system even in the harshest environments. We work with you to design a system to suit your needs an ensure the production of clean, energy-efficient, and dry compressed air.

Preventive Maintenance

Air compressor preventative maintenance (PM) is essential for the safe and energy efficient operation of your compressed air system. The time and costs associated with regular PM are negligible compared to the costs of an emergency repair that shuts your system down at a critical moment.

Air Compressor Repair Service

When your compressed air system is down or having issues, our knowledgeable service team is on-call around the clock and on weekends or holidays. We will do everything in our power to get you back up and running as quickly as possible.

24/7 Emergency Service

When you are a customer of Fluid-Aire Dynamics, you know that our outstanding customer support is backed by our 4-hour emergency service guarantee. If we do not have a certified technician on-site at your facility within 4 hours, the $250 elite service fee is waived.

Compressed Air System Design

Whether you’re putting in a new system or reconfiguring an existing layout, we bring our decades of experience to the design of complete compressed air systems. From the compressor room to the drops, we study your unique application and make sure you are producing air in the most efficient manner possible.

Equipment Installation

When a compressor or a complete system is being installed in a new or existing facility, it is important to consider heat ventilation, proximity to the power source, what voltage is available, clearance for maintenance, and expandability. Fluid-Aire has the experience from hundreds of installations to get things just right for your operation.

Compressor Equipment Rental

We maintain a large fleet of air compressors and air dryers for rent to keep you up and running. Our qualified installation team provides on-site assistance to minimize downtime. Everything from delivering and placing the unit to the wiring and piping: we do it all. When the rental is no longer needed, we remove the rental and even install your new or rebuilt compressor.

Tell Us About Your Compressed Air Needs

Whether you need equipment sales, rentals, installation, or repair, we've got you covered. Don't wait - contact us now to ensure your compressed air systems are in the best hands!

Contact usCompressed Air System Equipment and Supplies

-

Rotary Screw Air Compressors

PneuTech rotary screw compressors are efficient and reliable units that serve the smallest to the largest applications. With thousands of units in service around the world, Fluid-Aire Dynamics is proud to offer this line of finely crafted compressors in our markets in the USA. PneuTech offers the longest parts & labor warranties and has very liberal start-up, sampling and maintenance contract expectations.view all products -

Reciprocating Air Compressors

We sell, install and service high-quality reciprocating (piston-style) air compressors from PneuTech and other national brands, including Ingersoll Rand and Saylor Beall.view all products -

Air Dryers

Whether refrigerated dryers or desiccant dryers, the PneuTech line of dryers pairs perfectly with any of our compressors or with any other brand. The RDA line of non-cycling refrigerated dryers achieve excellent performance even in instances of high ambient and high inlet temperatures while yielding low humidity. The RDS line of desiccant dryers serve special applications requiring super-low dew points down to -40°F.view all products -

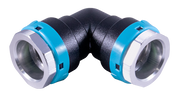

Aluminum Piping

Unipipe is the all-aluminum piping system that is made for compressed air and is warranted for 20 years against leakage or failure. It offers super-fast installation, requires no special tools or skilled labor, and has the largest available size range, with 13 sizes. The dynamic grip ring provides exceptionally secure joints and makes it impossible for the fitting to come off the pipe.view all products -

In-Line Filtration

PneuTech filter housings come standard with a differential pressure gauge and automatic float drain. All filter housings are 100% aluminum with an exterior powder coat finish. Offering five filter types: Particulate, Utility Grade, High Efficiency, 2-in-1 and Activated Carbon for use pre-dryer, post-dryer or at point of use.view all products -

Nitrogen Generators

A Nitrogen Generation system is a cost saving alternative to buying bottled nitrogen and leasing tanks. Featuring oversized absorption towers, large stable adsorption beds, and generous design layout. Maintenance and parts are easy to access and simple to service.view all products

Fluid-Aire Dynamics: Local Compressed Air Experts

Starting in a modest garage in Franklin Park, Illinois, Fluid-Aire Dynamics continues to grow through a network of ten Fluid-Aire branches in the largest manufacturing cities in the Midwest. We now serve maintenance clients within a 90-mile radius of our service facilities in Schaumburg, IL (Chicago), Franklin, WI (Milwaukee), Burnsville, MN (Minneapolis/St. Paul), Detroit, Philadelphia. We’re proud to provide exceptional service for our core brand, PneuTech, along with all other major brands of compressed air equipment.

-

Offering Extended Warranty

Fluid Aire Dynamics provides extended warranty options on all air compressor sales and services to give you complete peace of mind and protection on your system investment.

-

Serving All Popular Brands

Our certified technicians have extensive expertise working on all major commercial air compressor brands including Atlas Copco, Ingersoll Rand, Quincy, FS Elliott and more.

-

Serving Your Industry

With over 30 years of experience, we understand the unique compressed air system requirements for manufacturing, chemical processing, food/beverage, healthcare and other industries. Our solutions are tailored to your needs.

Contact a Compressed Air Specialist Near You

Fluid-Aire Dynamics is headquartered in Chicago and has local service offices in Milwaukee, Minneapolis, Detroit, Philadelphia. We provide service in a 90-mile radius of these metro areas. Contact us for compressed air equipment sales, rentals, installation, repair, and maintenance in your area.